Presto Pressure Canner⁚ A Comprehensive Guide

This guide provides a comprehensive overview of using your Presto pressure canner, encompassing pre-canning preparations, safe operation procedures, and post-canning steps. Consult your specific Presto model’s instruction manual for detailed specifications and safety guidelines. Remember to always prioritize safety and follow instructions meticulously.

Understanding Your Presto Model

Before embarking on your canning journey, familiarize yourself thoroughly with your specific Presto pressure canner model. Different models may have slight variations in features and operation. Locate your model number, usually found on a sticker affixed to the canner itself. This number is crucial for accessing the correct instruction manual and troubleshooting any potential issues. The manual will provide detailed diagrams and explanations of all parts, including the lid, pressure gauge, vent pipe, and safety mechanisms. Pay close attention to the capacity of your canner, as this dictates the number of jars you can process simultaneously. Understanding the functionalities of your Presto pressure canner’s control knobs, buttons, or digital displays (if applicable) is paramount for accurate pressure regulation and safe operation. Take note of any unique features your model possesses, such as specific safety locks or pressure release mechanisms. Proper understanding of your model ensures safe and successful canning.

Pre-Canning Preparations⁚ Cleaning and Inspection

Meticulous pre-canning preparation is crucial for ensuring the safety and success of your canning process. Begin by thoroughly cleaning your Presto pressure canner. Remove any leftover food particles or residue from previous uses. Wash all parts that come into contact with food with warm, soapy water, paying special attention to the gasket and lid. Rinse thoroughly and allow everything to dry completely before proceeding. A thorough inspection is equally important; carefully examine the pressure gauge for any damage or inconsistencies. Ensure the safety valve is clean and unobstructed, allowing for proper pressure release. Check the gasket for any signs of wear, tears, or damage; a damaged gasket compromises the seal, potentially leading to unsafe pressure buildup. The vent pipe should be free from obstructions; Inspect the locking mechanism to ensure it functions correctly and securely seals the lid. Any damaged or malfunctioning components should be replaced immediately before use to guarantee safe operation and prevent accidents. Don’t proceed with canning if any part is damaged or questionable.

Essential Safety Precautions⁚ A Checklist

Prioritize safety throughout the entire canning process. Before commencing, ensure you’ve thoroughly read and understood the instructions provided in your Presto pressure canner’s manual. Always use the correct amount of water as specified – insufficient water can lead to overheating, while excessive water may hinder proper pressure build-up. Never attempt to force the lid closed; it should seal easily and securely. Confirm the vent pipe is clear and unobstructed before initiating the canning process. During the canning process, never leave the pressure canner unattended. Monitor the pressure gauge consistently, ensuring it maintains the recommended pressure level for your chosen recipe and altitude. Never attempt to open the canner until it has completely depressurized naturally. Forcing the lid open prematurely is extremely dangerous. Following depressurization, use caution when removing the hot jars and allow them to cool gradually. Always handle hot jars and canner components with appropriate heat-resistant gloves or tools to avoid burns. Store canned goods in a cool, dark, and dry location, away from direct sunlight and excessive heat. Regularly inspect your Presto canner for any signs of wear or damage, and replace any worn-out parts promptly. Regular maintenance and adherence to these precautions are paramount for safe and successful pressure canning.

Preparing Food for Canning⁚ Recipes and Guidelines

Successful pressure canning hinges on meticulous food preparation. Begin by selecting recipes specifically designed for pressure canning; these recipes are crucial for ensuring food safety and optimal results. Adhere strictly to the recipe’s instructions regarding ingredient quantities, preparation methods, and processing times. Thoroughly clean and prepare all ingredients; this step minimizes the risk of contamination and spoilage. Ensure all produce is fresh and free from blemishes or signs of decay. For fruits, follow the recipe’s guidelines on pre-treatment, such as blanching or peeling. Vegetables often require blanching to inactivate enzymes that can affect color and texture during processing. Meats should be properly prepared according to the recipe instructions, ensuring they are cooked to a safe internal temperature. Always use high-quality jars and lids; ensure the jars are free of chips or cracks, and that lids and bands are new and undamaged. Proper jar sealing is crucial for preserving food quality and preventing spoilage. Before filling jars, ensure they are thoroughly cleaned and sterilized to prevent contamination. Follow the recipe’s instructions for packing the food into the jars, ensuring adequate headspace is maintained to allow for expansion during processing. Accurate headspace is vital for preventing jar breakage and ensuring a proper seal.

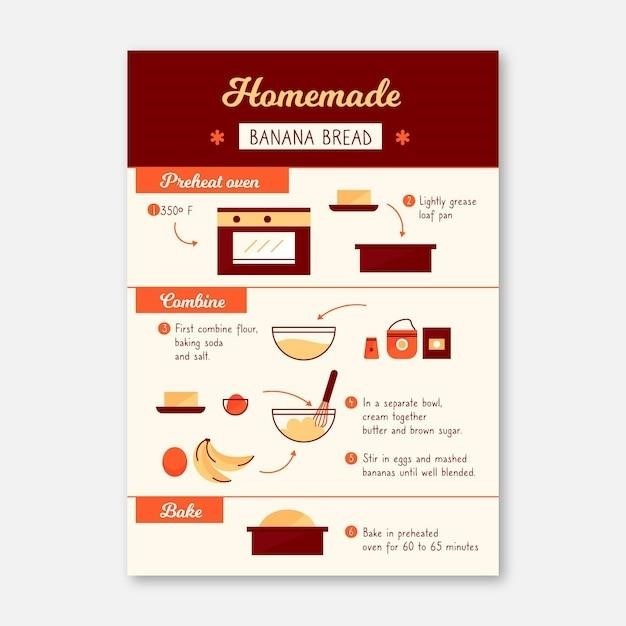

The Canning Process⁚ Step-by-Step Instructions

Once food is prepared and jars are filled, carefully place them on the canner rack, ensuring they’re not overcrowded. Add the required amount of water to the canner, typically three quarts, regardless of the jar quantity. Secure the canner lid and ensure the vent pipe is properly positioned. Begin heating the canner; the water will begin to vent steam. Allow venting to continue until a steady stream of steam escapes, indicating that all air has been expelled. Once venting is complete, adjust the pressure regulator to the appropriate level as specified in your recipe. Maintain the pressure for the designated processing time, carefully monitoring the pressure gauge throughout the process. Avoid opening the canner during processing; this can lead to loss of pressure and potential food spoilage. Once processing is complete, carefully turn off the heat source and allow the pressure to decrease naturally. Do not force depressurization. After the pressure gauge reads zero, wait an additional 10-15 minutes before carefully opening the canner lid, using caution to avoid steam burns. Remove jars from the canner using a jar lifter and allow them to cool completely. Listen for the “ping” sound indicating a proper seal. Check each jar for a proper seal by pressing the center of the lid; if it doesn’t flex, it’s sealed. Improperly sealed jars should be refrigerated and consumed promptly.

Achieving Proper Pressure⁚ Monitoring and Adjustments

Maintaining the correct pressure is crucial for safe and effective canning. After the initial venting period, the pressure should build steadily. Closely monitor the pressure gauge throughout the entire processing time. The required pressure will vary depending on the altitude and the specific recipe. Recipes often provide pressure adjustments for different elevations. If the pressure drops significantly below the recommended level, promptly investigate the cause. This could be due to insufficient water, a faulty pressure regulator, or a leak in the canner. If a leak is suspected, immediately cease processing and address the issue before continuing. Never attempt to force the pressure higher than the recommended setting; doing so could damage the canner or compromise safety. Conversely, if the pressure consistently exceeds the target, check for excessive water levels; too much water can impede proper pressure regulation. If adjustments are needed, carefully follow the manufacturer’s instructions for your specific Presto model. Accurate pressure maintenance ensures proper heat penetration, destroying harmful bacteria and achieving optimal food preservation. Remember, consistent pressure is paramount for successful and safe pressure canning.

Processing Times⁚ Understanding the Variables

Accurate processing times are critical for safe food preservation in your Presto pressure canner. These times are not arbitrary; they are scientifically determined to ensure that harmful bacteria are eliminated. Several factors influence the necessary processing duration. Altitude significantly impacts processing time; higher elevations require longer processing times due to lower boiling points. The type of food being canned also plays a crucial role. Low-acid foods, such as vegetables and meats, demand longer processing times compared to high-acid foods like fruits. The size and number of jars also affect the overall processing time. Larger jars may require slightly extended processing to ensure even heat distribution throughout their contents. Always consult a reliable, up-to-date canning guide or recipe book for the precise processing time for your specific food and altitude. Never deviate from the recommended processing time unless you have a well-documented and credible reason to do so. Insufficient processing can lead to spoilage and potential health risks. Conversely, over-processing might result in overly soft or mushy food. Accurate processing times ensure the safety and quality of your canned goods. Always prioritize safety and adhere to tested guidelines.

Depressurizing and Safely Opening the Canner

Once the processing time is complete, carefully depressurize your Presto pressure canner to avoid burns or other injuries. Never attempt to force the release of pressure. Allow the pressure to drop naturally to zero pounds before opening. This usually involves a slow, controlled release of steam. The specific method for depressurizing will depend on your Presto canner model; consult your instruction manual for detailed steps. For some models, this involves allowing the pressure to reduce naturally, while others might have a quick-release mechanism. Regardless of the method, always ensure the pressure gauge reads zero before attempting to open the lid. Opening the canner prematurely can lead to scalding steam escaping, causing serious burns. After the pressure has fully dropped, carefully turn the locking mechanism to unlock the lid. Slowly lift the lid away from you, tilting it slightly to allow any remaining steam to escape safely. Never place your face directly over the canner while opening it. After opening, carefully remove the jars, ensuring you use heat-resistant gloves or pot holders to protect your hands from the heat. Allow the jars to cool completely before handling them further. Improper depressurization can be dangerous, so always follow the manufacturer’s instructions carefully.

Post-Canning Procedures⁚ Cooling and Storage

After safely removing the jars from your Presto pressure canner, allow them to cool completely at room temperature, undisturbed, for at least 12-24 hours. Avoid placing them in a draft or on a cold surface, as rapid temperature changes can cause the jars to crack or break. During the cooling process, you should hear a gentle “ping” sound as the lids seal. This indicates a successful seal, ensuring the contents remain safe and preserved. However, some jars might not seal immediately, and that’s perfectly acceptable. After cooling, inspect each jar for a proper seal. A sealed jar will have a slightly concave lid and will not flex when pressed gently. If a jar doesn’t seal, refrigerate the contents immediately and consume them within a few days. Properly sealed jars can be stored in a cool, dark, and dry place for up to a year, or longer depending on the specific food canned. Always label each jar with the contents and canning date for easy identification and tracking. Before consuming, always check the jars for any signs of spoilage, such as bulging lids, leakage, or unusual odors. Discard any jars exhibiting these signs.

Troubleshooting Common Issues

If your Presto pressure canner isn’t reaching the correct pressure, check the vent pipe for obstructions and ensure the lid is securely fastened. Insufficient water can also hinder pressure buildup; always maintain the minimum water level specified in your instruction manual. If jars aren’t sealing, examine the lids for damage or improper placement. Ensure jars are clean and free of debris before filling. Improper processing times, due to incorrect pressure or insufficient time, can lead to spoilage. Always adhere to recommended processing times based on your recipe and altitude. If you notice bulging lids or leaking jars after cooling, this indicates a problem with the canning process. Discard these jars immediately. A persistent lack of pressure may indicate a malfunctioning pressure gauge or a leak in the canner itself. Consult your instruction manual for troubleshooting steps, or contact Presto customer support for assistance. Remember that proper cleaning and maintenance of your canner are crucial for preventing issues and ensuring optimal performance. Regular inspection of the seals and gaskets is also recommended to prevent future problems. Addressing these potential issues promptly will maintain the safety and effectiveness of your home canning efforts.

Maintaining Your Presto Canner⁚ Tips and Tricks

Regular cleaning is essential for the longevity and safety of your Presto pressure canner. After each use, allow the canner to cool completely before cleaning. Wash the interior with warm, soapy water, avoiding abrasive cleaners that could scratch the surface. Rinse thoroughly and dry completely before storing. Inspect the rubber gasket and sealing ring for any signs of wear or damage. Replace these components as needed to ensure a proper seal. Store your canner in a clean, dry place, preferably away from direct sunlight and extreme temperatures. Periodically check the pressure gauge for accuracy. If it seems inaccurate, consult your instruction manual or contact Presto for calibration or replacement. To prevent rust and corrosion, avoid leaving water inside the canner for extended periods; Proper storage will prolong the lifespan of your canner. Remember, a well-maintained canner contributes significantly to successful and safe home canning. Regular maintenance ensures your canner continues to function effectively and safely, protecting your food and preventing potential accidents. Don’t forget to check for any damage to the canner’s body or any of its components. Replacing damaged parts promptly will avoid future complications.